Effective Product Handling: Explore Affordable Prices on Cutting-Edge Star Screen Solutions

Effective Product Handling: Explore Affordable Prices on Cutting-Edge Star Screen Solutions

Blog Article

Boost Your Recycling Operations With Disc Screens

Reusing procedures play a vital duty in minimizing waste and preserving our setting. As the need for reusing remains to grow, it ends up being progressively essential to maximize the efficiency and efficiency of these operations. Enter disc screens-- a powerful device that holds the possible to revolutionize the sorting process. By utilizing advanced technology and innovative layout, disc screens provide a promising solution to increase recycling operations. In this discussion, we will certainly explore exactly how disc displays boost arranging effectiveness, maximize material splitting up, rise recycling rate, and improve overall effectiveness. Join us as we look into the world of disc displays and find the many methods they can improve your reusing procedures.

Just How Disc Screens Enhance Sorting Performance

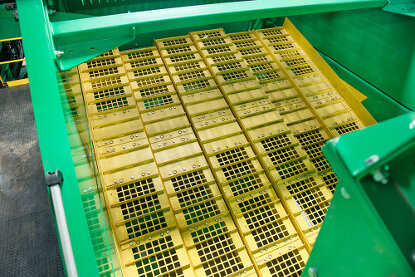

Disc displays play an essential role in enhancing sorting performance in reusing procedures. These displays are designed to different products based upon form, weight, and size, permitting extra effective sorting of recyclable materials. By using turning discs with tactically placed openings, disc displays can quickly and precisely separate different kinds of materials.

Among the vital methods which disc screens improve arranging performance is with their capability to deal with high volumes of material. The turning discs enable constant material feed, making sure a stable circulation of recyclable products with the arranging procedure. This eliminates the need for hands-on sorting and decreases the danger of traffic jams or clogs in the system.

In addition, disc displays are very customizable, enabling precise sorting based upon certain material demands. The dimension and spacing of the discs can be adapted to fit various product dimensions, guaranteeing that each product stream is appropriately arranged. This level of customization improves the total precision of the arranging procedure and lowers the probability of contamination or waste.

Moreover, disc screens are made to be durable and low-maintenance, lessening downtime and optimizing functional performance (star screen). They are constructed to withstand the needs of sturdy recycling operations and require marginal upkeep. This permits recycling facilities to preserve regular sorting effectiveness without substantial disruptions

Making The Most Of Material Separation With Disc Screens

With their ability to take care of high volumes of material and personalized design, disc displays play a vital role in making the most of product separation effectiveness in recycling operations. These displays are particularly designed to divide different types of products based upon dimension and shape, allowing for effective sorting and healing of recyclable products.

Disc screens work by rotating discs, which have various shapes and sizes of openings, to different materials as they pass through. The discs are installed on a shaft and prepared in a series, developing a screening surface. As products are fed onto the discs, smaller sized particles fail the openings while larger ones continue to travel along the surface area. star screen. This splitting up procedure allows the recovery of important products such as paper, cardboard, plastics, metals, and glass.

One of the vital benefits of disc screens is their capability to handle high quantities of material. Their big screening surface location enables for reliable handling, minimizing the time and labor required for hands-on sorting. Furthermore, disc screens can be personalized with different disc sizes and setups to fit the particular demands of recycling operations, better improving their material separation capacities.

Increasing Recycling Rate With Disc Screens

To boost recycling effectiveness, disc displays provide the potential to substantially boost the rate at which products are processed. Disc screens are an essential element in reusing operations, assisting to separate various kinds of materials efficiently. By carrying out disc displays in reusing facilities, drivers can streamline their procedures and enhance total productivity.

Making use of disc screens permits a continual flow of materials, which removes the demand for manual sorting and decreases downtime. These screens are furnished with rotating discs that have different dimensions and spacings, enabling the splitting up of various products based on their shapes and size. As materials overlook the discs, smaller sized items fail the voids, while bigger items continue down the conveyor belt.

Among the primary advantages of utilizing disc screens is their capacity to handle huge quantities of products rapidly. This enhanced speed of handling aids recycling centers to fulfill the growing needs for recycled materials. By decreasing the time it requires to type and different materials, disc screens allow recycling procedures to operate a lot more successfully and efficiently.

In enhancement to raising reusing rate, disc displays additionally add to the total high quality of the recycled materials. With their specific separation capabilities, disc displays can successfully remove pollutants and undesirable products from the recycling stream. This makes certain that the last product meets the preferred quality requirements, making it more marketable and important.

Improving Recycling Efficiency Via Disc Screens

Can disc screens be made use of to improve the performance of recycling procedures? The solution is a resounding yes. Disc screens are an innovative modern technology that can considerably enhance the reusing procedure by separating products extra effectively and successfully. By utilizing revolving discs with strategically placed openings, disc screens can divide numerous products based on shape, size, and density.

One of the essential benefits of disc screens is their ability to eliminate impurities from the recycling stream. The rotating discs permit the separation of smaller items such as paper, plastic, and steel, while bigger products like cardboard and glass remain on top of the display. This not just boosts the top quality of the recycled products yet likewise lowers why not look here the risk of damage to handling tools.

Additionally, disc displays can assist raise the healing prices of valuable products. By accurately separating various types of products, disc displays make it possible for recycling centers to extract a greater portion of recyclables from the waste stream. This not only takes full advantage of source recovery however additionally lowers the requirement for virgin materials, leading to an extra sustainable and eco-friendly recycling procedure.

In addition to boosting reusing performance, disc screens additionally provide functional benefits. They are made to be low-maintenance and long lasting, lessening downtime and raising total productivity. Furthermore, disc screens can be quickly incorporated into existing recycling systems, making them an economical option for enhancing recycling procedures.

Enhancing Performance With Disc Screens

Disc displays not just enhance the efficiency of recycling operations yet additionally improve efficiency in the process. By using this cutting-edge innovation, recycling centers can simplify their procedures and accomplish higher levels of efficiency.

One trick advantage of disc screens is their capacity to separate products effectively and properly. These displays are equipped with turning discs check my site that have various-sized openings. As materials go through the discs, smaller products drop with the openings while bigger things proceed down the conveyor belt. This procedure minimizes the requirement for hands-on sorting and conserves beneficial time.

Moreover, disc screens are designed to deal with huge quantities of products at a fast speed. With their robust building and construction and high-speed turning, these screens can efficiently process big quantities of recyclables in a much shorter amount of time. This boosted performance permits recycling centers to take care of more products, satisfy higher demand, and eventually create greater revenue.

Furthermore, disc screens are developed to reduce downtime and upkeep needs. Their sturdy elements and progressed design guarantee reputable performance, decreasing the demand for constant fixings and replacements. Therefore, operators can concentrate on making best use of performance instead of handling tools issues.

Final Thought

By making use of turning discs with tactically placed openings, disc screens can swiftly and precisely separate different types of materials.

The revolving discs allow for continual material feed, making certain a stable circulation of recyclable products through the sorting procedure.Disc screens function by turning discs, which have different dimensions and shapes of openings, to different materials as they pass through. Additionally, disc screens can be customized with different disc sizes and arrangements to suit the specific demands of reusing procedures, additionally improving their product separation capacities.

By using turning discs with purposefully placed openings, disc displays can separate different products based on density, shape, and Full Article size.

Report this page